TWI T3S Thermographic Turbine Test Station

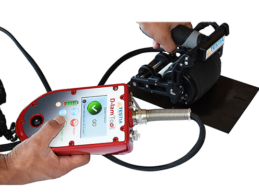

Thermal Wave Imaging (TWI) has released the new T3S Thermographic Turbine Test Station that performs a comprehensive site of turbine airfoil inspections in a single, consolidated system.

Description

This breakthrough technology platform uses advanced thermography to detect hole and channel blockages, measure wall thickness, detect de-lamination and detect cracks, in both land-based and aerospace-based turbine components. The T3S is comprehensive, modular and automated, enabling inspections to be completed in minutes.

The T3S thermographic turbine test station effectively replaces many of the traditional time-intensive turbine inspection methodologies with a single, comprehensive inspection system. Its modular architecture can be configured to meet your specific turbine inspection requirements.

Features and Benefits:

- Single test station for multiple applications.

- Non-contact inspection.

- Increased speed, accuracy and reliability.

- Complements other NDE test procedures.

- Developed under NAVAIR STTR.

- CE compliant.

Conventional NDT techniques used today to inspect for blockages, cracks, thickness and adhesion typically take days to complete. T3S offers improved performance and time savings in an order of magnitude. The net benefit is increased inspection sensitivity, increased throughput, and significant cost reduction and return on investment.

TWI’s ground-breaking TAFIS – Thermal Air Flow Inspection System specifically designed to detect blocked cooling holes in turbine airfoils, is built on the T3S platform.