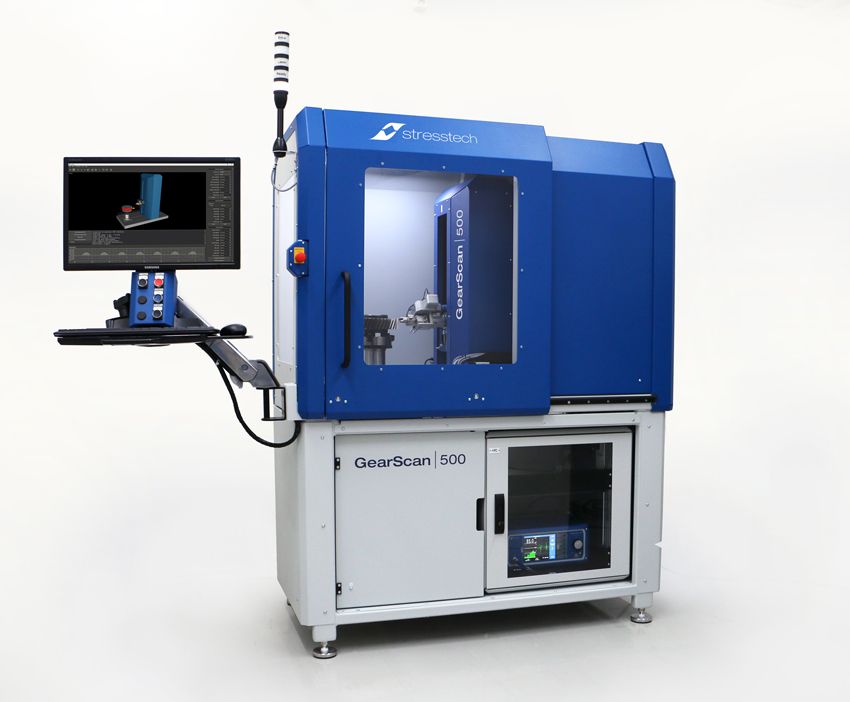

STRESSTECH GearScan 500 BARKHAUSEN NOISE ANALYSIS FOR GEAR INSPECTION

The GearScan 500 allows for fast detection of common manufacturing problems such as grinding re-temper burn, heat treatment and stress related defects. With GearScan 500 it is easy to control quality of helical and spur gears with Barkhausen Noise.

Description

GearScan 500 System allows for fast detection of common manufacturing problems such as grinding re-temper burn as well as heat treatment and stress related defects.

Technical Specifications:

- Repeatable and automated measurements.

- Non-destructive (NDT).

- No disposables and hazardous chemicals.

- Get quality data within a few minutes.

- Simple programming with EasyGear software.

- ViewScan software for data acquisition and analysis.

- Depth: 960 mm (37.8″).

- Width: 1584 mm (62.4″).

- Height: 2146 mm (84.5″).

- Weight: 500 kg (1100 lbs).

- Maximum sample diameter: 450 mm (17.7″).

- Maximum sample height: 600 mm (17.7″).

- Maximum measurement height: 300 mm (11.8″).

- Maximum sample weight: 30 kg (66 lbs).