Neutron Radiography Non Destructive Testing

Neutron radiography testing is an underused NDT (non destructive testing) technique. The process uses high yield neutron generators to capture a scan of the internal mechanisms of a sealed object. Like all non destructive testing, the technique works without causing any damage to the object that is being scanned.

Other NDT techniques used to scan the inner workings of an object include:

- Ultrasound

- Liquid penetrant testing

- Radiography

- Eddy current testing

- Coherence interferometry.

Of these methods, the most similar technique to neutron radiography NDT is radiography, specifically, Gamma and X Ray Non Destructive Testing.

How Does Neutron Radiographic Testing Work?

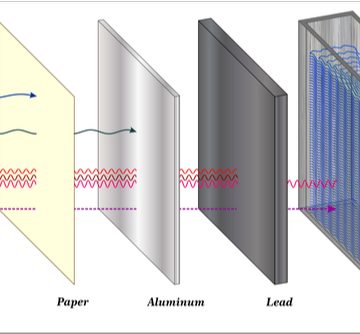

All radiography works by beaming a series of radiation particles at an object. Some of the particles will interact with the object and don’t pass through. Other particles will pass through the object and collide with an imaging agent. An image of the interior of the object being scanned is thus recorded according to the presence or non presence of particles that have passed through the object – like a screen print.

Gamma and X Ray particles interact with the electron cloud surrounding the atoms that make up the object. Neutron beams only interact with the nucleus – the centre of the atom. Nuclei are a lot smaller than the orbit of electrons. This means there is a much slimmer chance that the radioactive particles will be dispersed upon collision with the material.

Neutron Radiation VS Gamma Radiation

Gamma rays have been used widely by NDT professionals as a radiographic scanning tool. However, these often aren’t strong enough to pass through the atoms in denser materials. Neutron radiography, however, passes through heavy materials easily, making it a good choice when scanning heavier components.

One example of the applications of neutron radiography is the scanning of parts used in the aerospace industry, like turbine blades. These are often heavy and difficult to penetrate during a Gamma or X Ray radiography inspection. Furthermore, neutron radiographic technology is more effective than Gamma when detecting water and moisture inside parts.

Neutron Radiation VS X Rays

Conversely, lighter elements with a low atomic number often aren’t registered by neutron radiography. This means that X Rays and Neutron Radiography can be used in tandem. Doing so can produce a more comprehensive image of an object’s interior.

This technique has relatively limited research backing its effectiveness, however. This is because most X Ray imaging facilities don’t have access to neutron imaging technology. Similarly, nuclear research facilities don’t have access to X Rays.

Limitations

Historically, neutron tomography has relied on old nuclear reactors to operate. There is currently not enough Neutron Radiography NDT technology on the market to meet demand.

This means that parts destined for internal scans need to be shipped to nuclear research facilities. These research facilities have access to enough neutrons for imaging. This tenant of the operation requires heavy security, safety and logistics to be successful. This causes a lot of problems when the technology is needed for smaller applications.

Contact NDT for all non destructive testing technology sales.