ROHMANN SCANALYZER SOFTWARE

The ScanAlyzer-system combines powerful software with modern eddy-current inspection technology. It features numerous tools to allow the easy interpretation of eddy-current signals, also ensuring that the inspection of safety-relevant parts in production and maintenance is documented.

Description

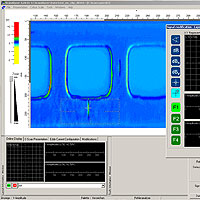

The Rohmann ScanAlyzer is universal software for eddy current inspection, documentation and analysis, and is also suitable to quickly and reliably generate C-scans. Due to its serial-scan function, it can be used to monitor production and maintenance. The Rohmann ScanAlyzer-system combines powerful software with modern eddy-current inspection technology. It features numerous tools to allow the easy interpretation of eddy-current signals, also ensuring that the inspection of safety-relevant parts in production and maintenance is documented. The Rohmann ScanAlyzer has been approved by leading manufacturers of aircraft engines, chemical companies and power plant operators.

Modular and expandable:

In combination with the ELOTEST PL/IS500 or the ELOTEST PL/B300 you have a modular system that can be expanded and adapted to a wide variety of requirements.

The most important advantages at a glance:

- Modular design.

- Possible adaptation of various test instruments via DLL-driver (even products by other manufacturers).

- Possible long-term defect monitoring.

- Fast display due to 32-Bit programming.

- Easy operation.

- The operator requires no prior knowledge of eddy-current technology as the administrator can preset all parameters.

- The high informational content of the C-scan images allows the restoration of the complex eddy-current signals, zoom-function and up to 10 highlighting and log areas for separate print-outs.

- Unambiguous determination of the defect with information on size, angle and coordinates.

- Automatic storage of the measuring data (evaluation and generation of reports based on the default settings installed by the administrator).

- The “human factor” i. e. the influence of human weaknesses is minimized.

Functions include:

- Offline-display, selectable phase and vector length.

- Color scales for real, positive, absolute, gate-dependent values.

- Color scale with offset (may be spread/flattened).

- Color scale dependent on the phase angle and amplitude.

- Offline-phase rotation and gain Reconstruction of complex X/Y-signals.

- Geometric measurement of the defects via the cursor.

- Signal measurement (Amplitude and phase) in the C-scan image.

- Separate documentation of up to 10 defects with the corresponding zoom from the C-Scan.