Kaisei Engineer Co™ Eddy Current MDK System- KE 9500

Precise, advanced, cost-effective inspection

Description

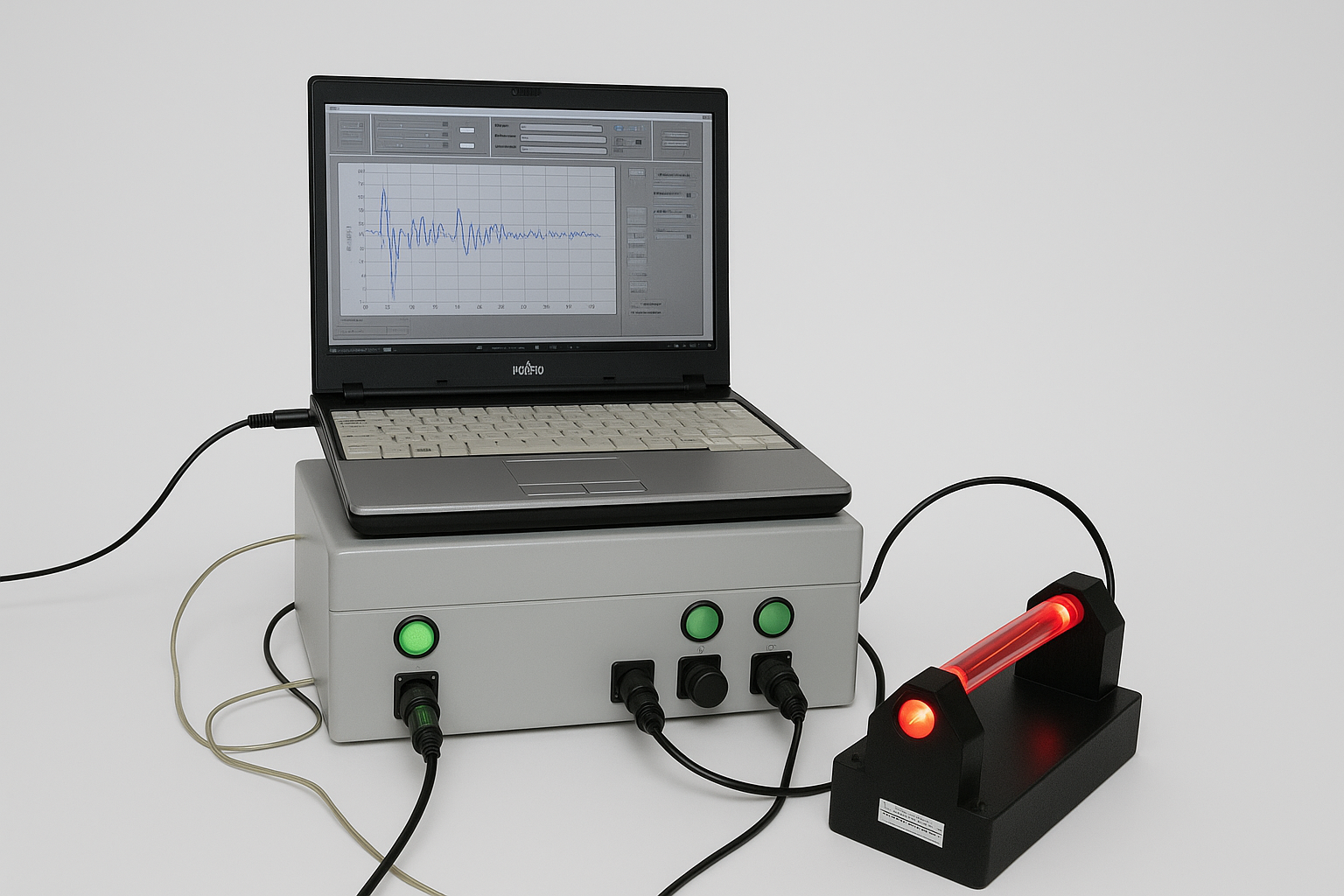

MDK NDT Inspection System – Precision from Japan

Discover an innovative way to safeguard your plant with the MDK NDT Inspection System—reliable inspection technology crafted in Japan and trusted globally, brought to you by Kaisei Engineer Co.

Using advanced electromagnetic induction, the system delivers ultra-sensitive detection of hidden problems such as corrosion, cracks, metal fatigue, and coating defects—without the high costs of X-ray inspection.

Designed for portability and reliability, the MDK system is lightweight, waterproof, and connects easily to your PC via USB for instant analysis. Its customizable sensing coils adapt to various shapes and surfaces, ensuring accurate inspection every time.

Key Features:

- Lightweight and portable: Amplifier (5 kg) and sensor (0.8 kg)

- Compact dimensions: 300 × 135 × 200 mm

- Simple waterproof design

- Power: 90–240 V AC

- Output: USB connection for PC data analysis

Global Distributor

The MDK NDT system is already in use across Japan and internationally, offering an upgraded inspection method that is both cost-effective and dependable for safeguarding industrial plants.

Experiment to detect inner pipe flaws from the outside of SUS double pipe.

Experiment to detect corrosion and thinning of a pipe coverd. – YouTube

Experiment to inspect the state of 4 points projection welding.

Experiment to detect defects of molding (press) by an electromagnetic induction method.

Experiment to detect flaws on CFRP by an electromagnetic induction method.

Experiment to detect flaws on a steelwire in concrete by an electromagnetic induction method.

Non-destructive inspection system by electromagnetic induction method for concrete structure