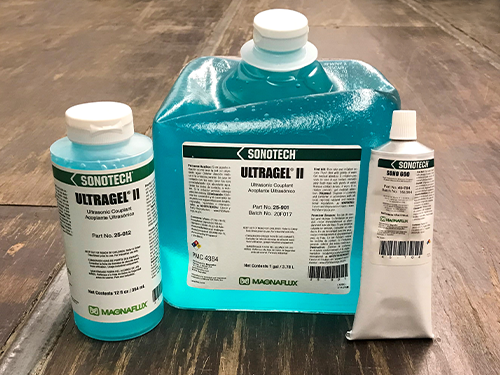

Sonotech Ultragel II UT / Sono 600 High-Temperature Ultrasonic Couplant

Description

Ultragel II is an industry-leading, high-performance, ultrasonic couplant for flaw detection and sizing, thickness gauging, flow metering and acoustic emission testing.

It is widely recognized as the industry’s most dependable and popular ultrasonic couplant. This general-purpose medium viscosity gel is known for its outstanding performance, excellent corrosion protection, thixotropic properties and comprehensive range of specifications and approvals.

ULTRAGEL II meets the Halogens and Sulfur requirements specified in NAVSHIPS MIL-STD-767. ULTRAGEL II meets ASTM F519 Hydrogen Embrittlement test on high strength steel, and has been tested for composite shear modulus, and aircraft aluminum corrosion and composite adhesion.

Benefits

- Clings well to vertical and overhead surfaces

- Fills in depressions in rough surfaces

- Highest corrosion protection

- Slow drying for longer inspection time

- Provides good transducer lubrication

- Increased acoustic impedance reduces surface noise

- Wide range of specifications and approvals

- Thixotropic gel

- Great surface wetting

- Nuclear grade

- Aerospace approvals

- Hydrogen embrittlement testing

Click here for Safety Data Sheet

Sono 600: High-Temperature Ultrasonic Couplant

Sono 600 is a versatile, multi-purpose couplant with a wide operating temperature range for flaw detection, thickness gauging and acoustic emission testing in petrochemical, power generation, automotive, aerospace, food processing equipment and pharmaceutical manufacturing.

Recommended temperature range is 0 to 700°F / -18 to 371°C.

Benefits

- Economical high-temperature couplant

- Excellent corrosion inhibition

- Very slow drying for extended inspection time or long-term coupling

- Non-toxic, biodegradable formula