TruView CUBE BENCHTOP X-RAY INSPECTION SYSTEM

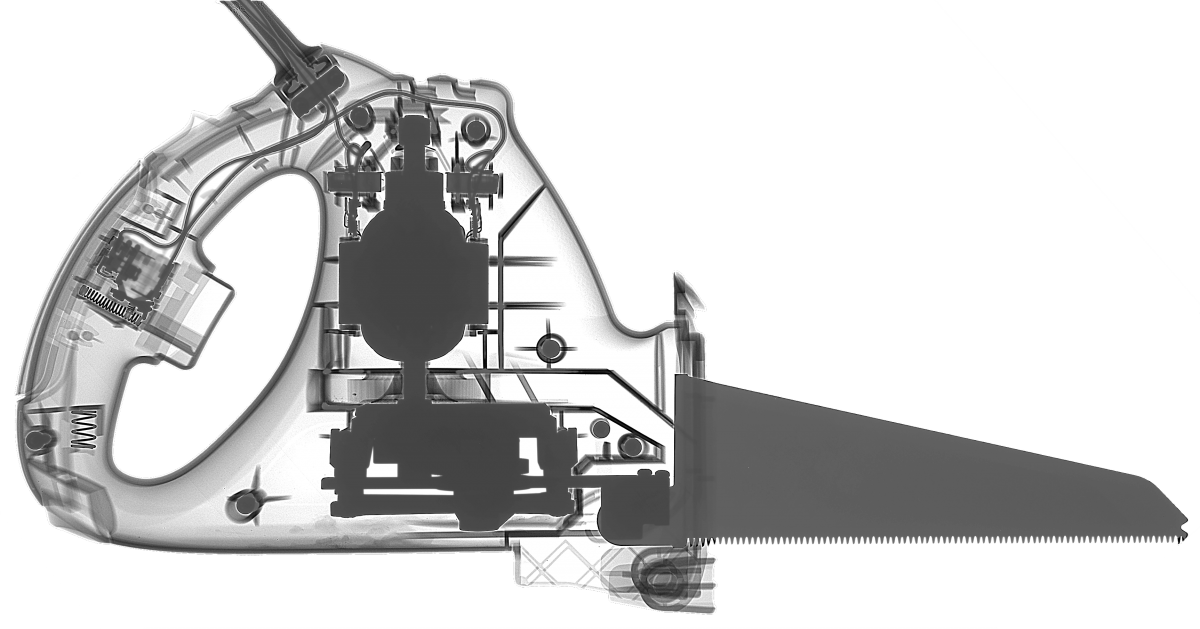

The all new TruView™ Cube-A X-Ray Inspection System from Creative Electron, USA, is a fully motorized radiography system developed to meet the stringent requirements of electronics assembly and component inspection.

Description

The all new TruView™ Cube-A X-Ray Inspection System from Creative Electron, USA, is a fully motorized radiography system developed to meet the stringent requirements of electronics assembly and component inspection. Ideal for applications where space is premium, the TruView™ Cube X-Ray sits comfortably on the laboratory bench.

The TruView™ Cube-S is designed for NDT applications and semiconductor parts counting. A large flat panel is installed right underneath the system’s platform for superb image quality. One platform, two powerful configurations.

Technical Specifications:

- X-Ray Source: 80 kV.

- Spot Size: Micro-focus.

- System Resolution: Final image resolution depends on the sample.

- X-ray Sensor: Model (S): 3″ x 4″ or 5″ x 6″ – 14-bit flat panel. Model (A): 4 1/2″ – Image Intensifier.

- Sample Manipulation: Motorized X, Y, motion. Sample rotation available as option (A and S).

- System Dimensions: 16″ x 16″ x 28″ (A and S).

- Maximum Visible Area: 6″ x 6″ (A and S).

- Included Software: TruView 6 Software. Please check TruView App Store for available applications.

- Included Computer: PC with Windows OS, fully networkable.

- Safety: FDA compliant and CE certified. Cabinet is fully shielded with multiple interlocks, keyed start switch and emergency stop switch. Certified to operate world-wide.

Configuration:

TruView™ Cube A: Load and unload samples using the front door in the system. Fully motorized motion system.

TruView™ Cube S: Source on the top of the system and a large flat panel detector on the bottom, allowing samples to lie right on top of the sensor. Ideal for NDT applications and parts counting.

For further information please email: ndt@ndt.com.au