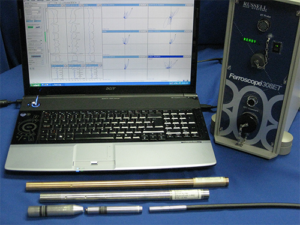

RUSSELL NDE FERROSCOPE 308 REMOTE FIELD TESTING SYSTEM

The Ferroscope 308, manufactured by Russell NDE Systems, is a remote field testing system for tube, pipe and plate.

Description

The Ferroscope 308, manufactured by Russell NDE Systems, is a remote field testing system for tube, pipe and plate.

Applications:

- Non-destructive inspection of carbon steel, copper, brass, cupro-nickel, ferritic and other alloys.

- For tube inside diameter 0.250 inch (6.35 mm) and up.

- Common usage includes boiler tubes, heat exchanger tubes, and storage tank roofs, floors, walls.

- Used in power generation, oil and gas, pulp and paper, and petro-chemical plants.

- Supports T4 + Saturn techniques for finned tubes.

- Small and large bore applications

- Complies with ASTM standard practice E2096.05 for RFT (Remote Field Testing) of ferrous exchanger tubes.

- Designed to meet many special applications such as flat plate and pipe inspection from the inside or outside.

Features:

- Superb pit detection capabilities.

- Dual frequency processing for high sensitivity near tube supports.

- High-quality, low noise instrumentation for a wide variety of applications.

- Backed by Russell’s highly-rated RFT training and technical support.

- Adept-Pro Software: Integrates examination planning, data acquisition, analysis, and report generation.

- Voltage plane display and analysis for maximum flaw information.

- Specialized Remote Field analysis channels including support plate suppression and uniform wall loss signal filter.